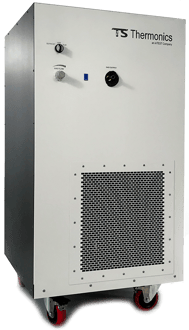

At Thermonics, our chillers are born for the most demanding cooling applications.

We Keep Everything Cool with Reliable, Low Temperature Chillers.

Low Temperature Chillers

Low Temperature Fluid Chillers

We design low (-80.0°C) and ultra-low temperature (-120.0°C) chillers for cooling fluids and gasses in process cooling applications.

Cannabis Extraction Chillers

Low Temperature Chillers for Rapid Ethanol and Solvent Cooling

Our extraction chillers are designed for hemp, cannabis, and other botanical extraction applications requiring precise, low temperature.

LN2-Cooled Chillers

Chillers for Ultra-Low Temperatures, Rapid Cooling

Our Cryo Chillers use liquefied cryogens to cool heat transfer fluids with a proprietary cooling technology, delivering low and ultra-low temperatures and rapid transitions rates to a test device or process.

Gas Chillers

Gas Chillers for Cooling Nitrogen, Argon, and other Gasses

Thermonics gas chiller systems are designed for cooling gasses (nitrogen, argon) and clean-dry-air (CDA) for a variety of process cooling applications.

PAO Chillers

Low Temperature PAO Chillers for Mil/Aero & Industrial Process Cooling Applications

These are designed for heat removal in military, aerospace, and industrial cooling applications where polyalphaolefin liquid is required as the heat transfer fluid.

About Thermonics Chillers

Low and Ultra-Low Temperature Process Chillers